Sustainable Practices in Vehicle Manufacturing

The automotive industry is undergoing a significant transformation, with a growing emphasis on sustainability across its entire value chain. Vehicle manufacturing, traditionally resource-intensive, is now adopting innovative practices to minimize environmental impact. This shift encompasses everything from sourcing raw materials and optimizing production processes to enhancing vehicle operational efficiency and managing end-of-life recycling. Exploring these sustainable approaches reveals how manufacturers are working towards a more environmentally responsible future for global mobility.

The global automotive industry is increasingly prioritizing sustainability, driven by environmental concerns, regulatory pressures, and consumer demand for more eco-friendly products. This paradigm shift involves a comprehensive re-evaluation of how vehicles are designed, produced, and managed throughout their lifecycle. Manufacturers are integrating sustainable practices into every stage, from material selection to energy consumption in factories and the eventual recycling of vehicle components. This commitment aims to reduce the ecological footprint associated with vehicle production and use, fostering a greener approach to transportation worldwide.

Advancing Sustainable Materials and Design in Vehicle Manufacturing

Sustainable practices begin at the initial stages of vehicle design and material selection. Manufacturers are actively researching and implementing lightweight, recyclable, and bio-based materials to reduce the environmental impact of their products. This includes using recycled plastics, aluminum, and steel, as well as developing new composite materials that offer both strength and reduced weight, contributing to better fuel efficiency for the end-user. The aim is to minimize waste and the demand for virgin resources, while also ensuring the safety and performance of the vehicle. Modular design approaches also facilitate easier repairs and upgrades, extending the lifespan of vehicles and reducing the need for premature replacements.

Energy Efficiency in Production and Vehicle Operation

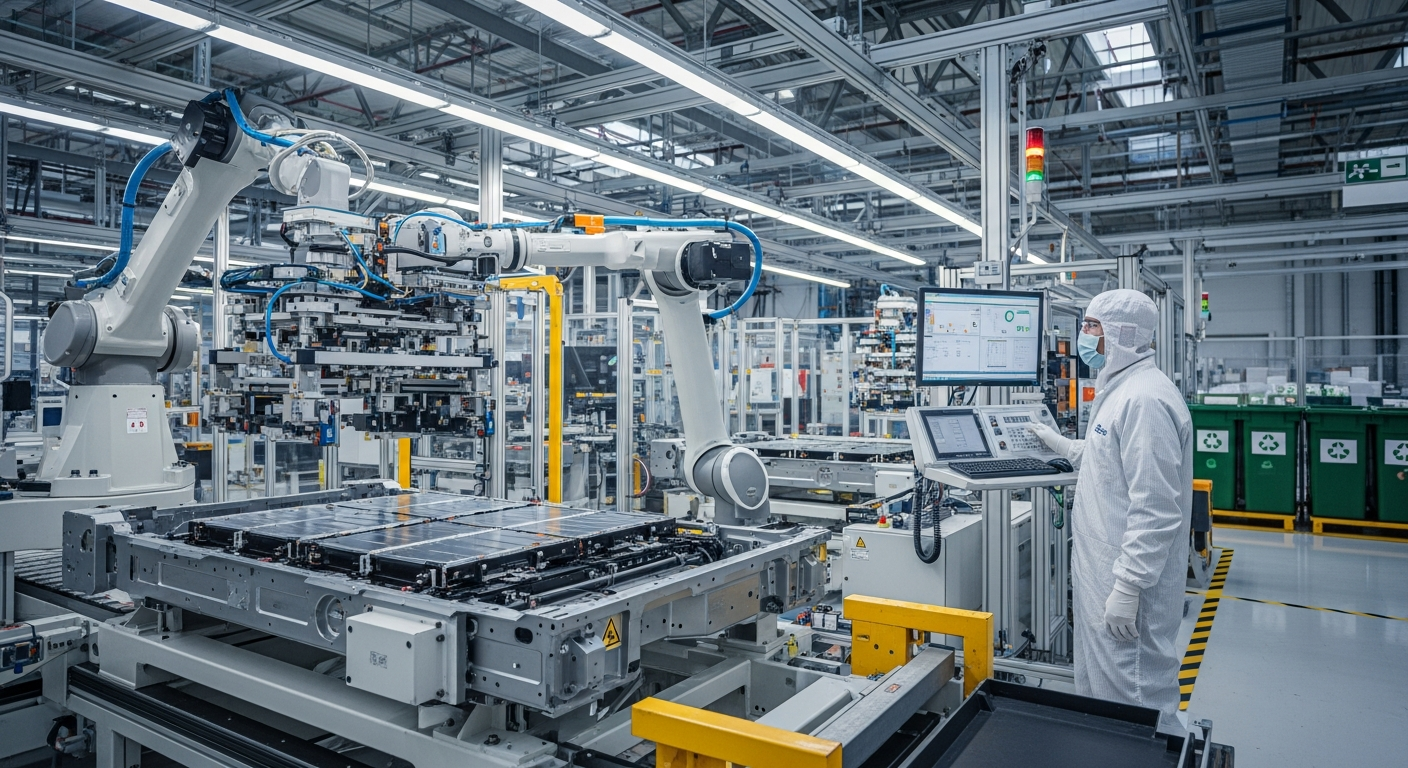

Energy consumption is a critical area for sustainability in manufacturing. Automotive plants are investing in renewable energy sources, such as solar and wind power, to reduce their reliance on fossil fuels. Process efficiency improvements, like advanced robotics and optimized production lines, also cut down on energy usage. Beyond the factory, the focus extends to the operational efficiency of the vehicles themselves. Innovations in engine technology, aerodynamics, and lightweight components are crucial for reducing fuel consumption in conventional vehicles. For electric and hybrid vehicles, efficient charging infrastructure and battery management systems are paramount.

Reducing Emissions and Waste Throughout the Vehicle Lifecycle

Minimizing emissions is a central goal for sustainable vehicle manufacturing. This includes not only tailpipe emissions from the vehicles but also greenhouse gas emissions generated during the manufacturing process. Factories are implementing advanced filtration systems and waste heat recovery to reduce their environmental footprint. Furthermore, strategies for waste reduction extend to water conservation and the responsible disposal or recycling of manufacturing byproducts. The lifecycle approach also emphasizes responsible end-of-life vehicle maintenance and recycling programs, ensuring that components like tires, brakes, battery packs, and other materials are recovered and reused, preventing them from ending up in landfills.

The Role of Electric and Hybrid Technologies in Sustainable Mobility

The shift towards electric and hybrid vehicles represents a major pillar of sustainable mobility. These vehicles offer significantly lower, or zero, tailpipe emissions, especially when powered by renewable energy sources. Advances in battery technology are critical, focusing on increased range, faster charging times, and improved durability. The manufacturing of these components, particularly battery cells, is also becoming more sustainable, with efforts to reduce the use of rare earth metals and improve recycling processes. The integration of electric powertrains is transforming the driving experience, making it quieter and more responsive, while also supporting broader environmental goals.

Future Directions: Autonomous Systems and Advanced Sensors

Looking ahead, technology continues to drive advancements in sustainable mobility. The development of autonomous driving systems, for instance, holds potential for optimized driving patterns that could enhance fuel efficiency and reduce congestion, further cutting down on emissions. These systems rely on sophisticated sensors and artificial intelligence to navigate and operate vehicles safely and efficiently. Research into advanced materials for tires and brakes also aims to reduce particle emissions and extend product life. The continuous innovation in these areas underscores the industry’s commitment to creating vehicles that are not only high-performance and safe but also environmentally responsible throughout their entire existence.

Sustainable practices in vehicle manufacturing are transforming the automotive industry. From the initial design phase and material selection to energy-efficient production, emissions reduction, and comprehensive recycling programs, every aspect is being re-evaluated through a sustainability lens. The rise of electric and hybrid vehicles, alongside ongoing technology advancements in autonomous systems and sensors, signifies a profound shift towards a greener future for mobility worldwide. This holistic approach is essential for mitigating environmental impact and ensuring the long-term viability of transportation systems for generations to come.